In the current scenario where manufacturing is extremely competitive and precision-oriented, Original Equipment Manufacturers (OEMs) find themselves in a situation where they are always under pressure to produce goods that are not only new and creative but also very trustworthy. The tiniest dimensional deviation in any of the products such as an automotive braking system, an aviation actuator, a medical device, or a high-speed spindle can result in disastrous failure, expensive recalls, or non-compliance with regulations.

Thus, it is not surprising that high-precision CNC machining has become the mainstay of the contemporary OEM manufacturing strategies. Apart from being fast and automated, CNC machining provides OEMs with much more: accuracy that is predictable, repeatability, surface finish that is controlled, and process stability even over large production volumes.

OEMs have moved past just outsourcing machining. They have made a decision to partner with advanced CNC machining specialists who comprehend the essential tolerances, quality control systems, and demands of the practical application in the long run. Such companies as Orbitol Intelligence Pvt. Ltd. have established themselves as reliable manufacturing partners by offering consistent performance and quality through their precision-driven CNC, VMC machining, and turning capabilities.

The article discusses thoroughly the reasons OEMs prefer high-accuracy CNC machining for critical parts, its impact on product reliability and lifecycle cost as well as the differentiating factors of a truly capable CNC machining partner in today’s market.

Comprehending the High-Accuracy CNC Machining

High-accuracy CNC machining is the term used for computer-operated manufacturing processes that can produce parts with such small tolerances that the measurements are often in microns. CNC machining, in contrast to traditional machining, guarantees digital precision, toolpath control, and repeatability over thousands of identical parts, thus minimizing the influence of manual skills on the outcome.

What Characterizes High Accuracy in CNC Machining?

The accuracy of CNC machining is affected by several interdependent variables:

- Rigidity of machine tools and their calibration

- CNC controllers’ precision

- Cutting tools’ quality

- Thermal stability

- Process control and quality control systems

- Programming and setup done by skilled professionals

Accuracy is a must for OEMs making critical parts, as it is not a choice but a requirement.

Regular Accuracy Standards in CNC Machining

| Sector | Tolerance Range Usually |

| Automotive | ±10 to ±20 microns |

| Medical Devices | ±2 to ±5 microns |

| Aerospace | ±5 to ±10 microns |

| Micro Machining Applications | < ±2 microns |

| Industrial Automation | ±10 microns |

CNC machining of high accuracy guarantees that every piece will sustainably pass the test, no matter how big the batch is.

Why are Critical Parts Requiring CNC Machining instead of Conventional Methods?

Critical parts are the parts that, if they failed, could risk safety, functionality, or system performance. OEMs need these components to be perfect with no variations, rework, or unexpected wear.

Main Arguments for CNC Machining to be the First Choice

- Identical Results in High Amounts

- Better Surface Finish and Control Over Surface Roughness

- Excellent Dimensional Stability

- Proficient Process Control

- Quality Control Systems Acquired

In conventional methods of machining, variability is often unintentionally caused by the operator’s skills. With CNC machining, this risk is completely eliminated as every operation is performed according to a validated digital process.

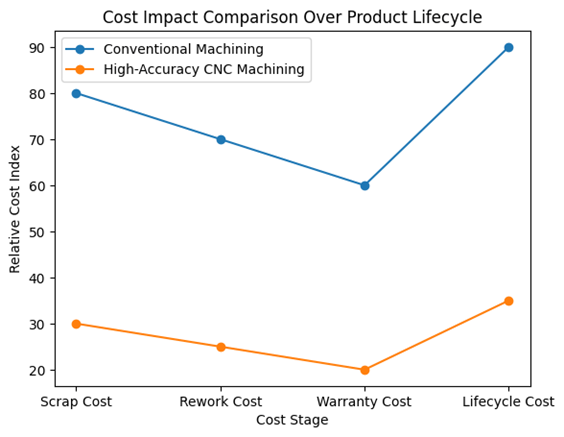

Cost Impact Comparision Over Product Lifecycle

Below is ready-to-use content for this single graph, written in a professional, human tone and using only ONE keyword once.

This diagram shows the effect of different types of manufacturing on the total cost of the product lifecycle from the very beginning to the end. Sometimes, when looking at only the initial production costs, traditional machining seems to be the most economical option, but on the other hand, if we take into account the cumulative effect of higher scrap rates, reworking very often, and warranty claims for defective parts, then the costs for all these things will be significantly increased in the long run. This issue is very important for OEMs who manufacture parts with a high value or safety sensitivity.

Cutting-edge CNC applications not only eliminate variance but also enhance the overall product lifecycle by translating it into fewer rejected parts and a more consistent performance in the actual market. By reducing the number of failures in the downstream process and guaranteeing predictable output, CNC machining facilitates OEMs not only to win over the marketplace with the appeal of cost efficiency in the long run but also to retain reliability, consistency, and customer trust.

The Importance of Surface Finish and Surface Roughness in OEM Parts

Dimensional accuracy is just one of the many factors OEMs consider. The performance of the component, the life cycle of the component, the sealing capability, the friction between the components, and the wear resistance can all be directly influenced by the surface finish and roughness.

The Importance of Surface Finish

- Friction in moving parts is reduced

- Improved fatigue strength

- More resistance against corrosion

- Hydraulic and pneumatic systems receive proper sealing

Standard Surface Finish Requirements

| Application | Required Surface Roughness (Ra) |

| Hydraulic valves | 0.2 – 0.4 µm |

| Medical implants | 0.1 – 0.3 µm |

| Aerospace bearing seats | 0.2 – 0.5 µm |

| Precision shafts | 0.4 – 0.8 µm |

OEMs consistently rely on high-precision CNC machining along with centerless grinding and fine finishing operations to satisfy these stringent requirements.

In the case of Orbitol Intelligence Pvt. Ltd., the company is committed to surface integrity in every CNC turning, milling, and grinding process and this guarantees that the components will perform under real-world conditions just as they were designed.

CNC Machining vs Grinding: How OEMs Use Both Strategically

CNC machining is capable of producing a part that has accurate dimensions, features, and shapes, while the grinding processes are less visible but still very important to ultra-tight tolerances finishing.

Grinding Machines Types Used for Critical Parts

| Grinding Type | Typical Application |

| Centerless grinding | Shafts, pins, rods |

| Surface grinding | Flat precision surfaces |

| Cylindrical grinding | Bearing journals |

| Tool and cutter grinding | Cutting tools |

Centerless grinding is one of the processes that offer OEMs the most advantages when producing a large number of cylindrical parts that need to be very round and having a good surface finish.

The combination of CNC machining and grinding produces a hybrid precision workflow, which allows OEMs to attain outstanding accuracy and consistency.

VMC Machining and CNC Turning in OEM Manufacturing

VMC Machining for Complex Geometries

VMCs are extensively used by OEMs for:

- Complex 3D components

- Precision housings

- Structural parts

- Multi-feature machining

Modern VMC machining gives the opportunity to have several operations in one setup, which decreases errors due to moving the part around.

CNC Turning for Rotational Accuracy

CNC turning is a must for the production of parts including but not limited to:

- Shafts

- Bushings

- Couplings

- Spindles

Top-class CNC lathes guarantee the essential properties of rotating components, namely concentricity, roundness, and surface finish.

Orbitol Intelligence Pvt. Ltd. has VMC machining, CNC turning, and finishing processes all under one roof which means that the entire process from raw material to finished component is totally in control.

Micro Machining: The Future Needs of OEMs are being Met

The smaller and more sophisticated the products get, the more micro machining becomes a necessity. This is particularly true in the following industries:

- Medical devices

- Electronics

- Aerospace sensors

- Precision instruments

Micro machining needs:

- Super-stable machines

- Fast spindles

- Custom tools

- Sophisticated measuring systems

Original Equipment Manufacturers (OEMs) like to work with CNC partners who have micro machining knowledge and experience since even a deviation of one micron can change the functionality. This is a case where advanced CNC infrastructure investment clearly distinguishes one supplier from another.

Quality Control and Process Control: The OEM Confidence Factor

OEMs buy not only parts, but also confidence.

The Role of Quality Control in CNC Machining

Quality control makes sure that every part corresponds to:

- Dimensional requirements

- Surface treatment standards

- Material specifications

Some of the common quality control tools are:

- Coordinate Measuring Machines (CMM)

- In-process gauges

- Surface roughness testers

- Statistical Process Control (SPC)

Process Control for Long-Term Consistency

Process control is primarily concerned with defect prevention, instead of merely defect detection.

The most important process control practices are the following:

- Tool life monitoring

- Machine calibration schedules

- Cutting parameters control

- Data-driven optimization of the process

Orbitol Intelligence Pvt. Ltd. employs strict quality and process control systems which fulfill the OEM requirements, thereby making it possible to deliver consistently throughout the batches and the long-term programs.

Cost Efficiency Without Sacrificing Precision

The idea that precision CNC machining will always be the most costly option over time is untrue.

The Role of CNC Machining in the Reduction of Total Cost of Ownership

| Cost Factor | Conventional | High-Accuracy CNC |

| Scrap rate | High | Low |

| Rework | Frequent | Minimal |

| Inspection cost | High | Optimized |

| Field failures | Possible | Rare |

| Lifecycle cost | High | Lower |

The OEMs know that the initial step’s precision results in the future savings, particularly for the products that are safety-critical and high-value.

Case Perspective: OEM Expectations from CNC Partners

OEMs usually expect their CNC machining partners to assist in the following areas:

- Design-for-manufacturing support

- Stable and repeatable processes

- Full traceability

- Continuous improvement mindset

Orbitol Intelligence Pvt. Ltd. is working hand in hand with the engineering teams of the original equipment manufacturers (OEMs) to enhance the manufacturing processes so that they are aligned with the design intent, which will ultimately facilitate the transfer of the product from the prototype to the mass production stage without any issues.

The Strategic Advantage of Partnering with Orbitol Intelligence Pvt. Ltd.

What sets Orbitol Intelligence Pvt. Ltd. apart is not just the kind of machinery but also the smartness of manufacturing.

Major Strengths

- Top-notch CNC machining infrastructure

- Expertise in VMC machining and CNC turning

- Control of surface finish and accuracy at a high level

- Quality and process control systems that are very strong

- Strategy that is OEM-oriented

With a combination of vast technical know-how and systematic execution, Orbitol Intelligence Pvt. Ltd. extends its support to OEMs in the automotive, industrial, medical, and high-precision engineering sectors.

The Future of High-Accuracy CNC Machining for OEMs

The future of OEM manufacturing will be determined by:

- Digital manufacturing

- Predictive quality analytics

- Automation and robotics

- Higher accuracy requirements

- Micro and nano-scale machining

OEMs will consider CNC machining partners, who have made investments in technology, skills, and systems, as their most important source of support to overcome these trends.

Conclusion: Why High-Accuracy CNC Machining Is Non-Negotiable for OEMs

In the case of OEMs whose main business is to procure the parts of the highest possible quality, high-accuracy CNC machining is more of a manufacturing method than a big tech investment.

CNC machining opens up the possibility of application for OEMs in the global markets of the highest demand and the most reliable machinery with long-term maintenance and last long-precision and surface finish quality control.

Working with manufacturers that focus on precision engineering like Orbitol Intelligence Pvt. Ltd. gives OEMs more than just a component. They become a trustworthy additional part of the engineering and quality assurance teams.In times when going down is not an option, high-accuracy CNC machining continues to be the backbone of OEM triumph.