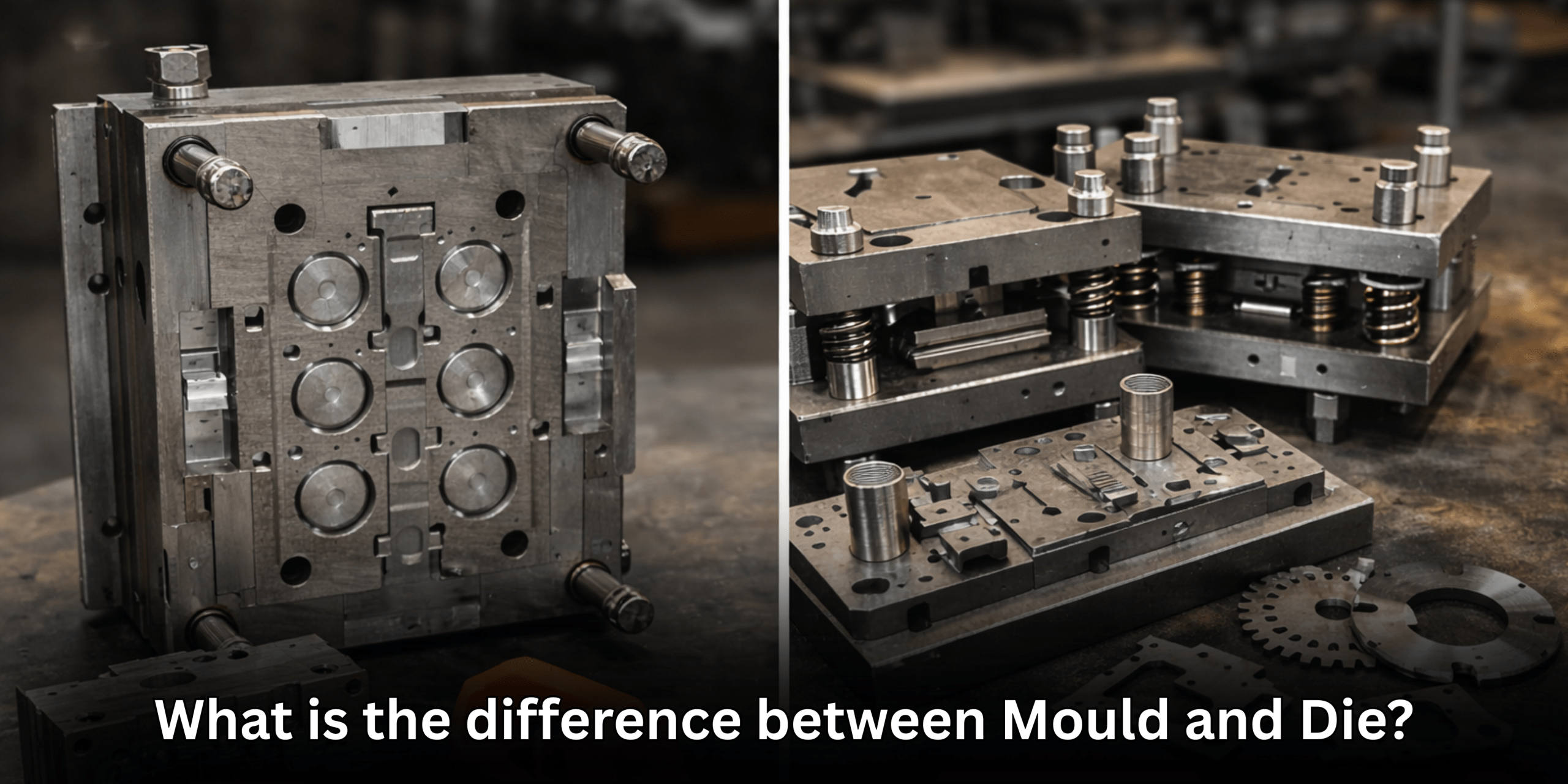

A single glance at tooling in manufacturing shows two key players – molds and yet dies – often mistaken as identical. While both give form to raw matter, their roles split sharply when it comes to method or purpose. A single method manages gooey stuff hardening into forms. Meanwhile, a different one slashes, twists, or reshapes stiff plates using pressure. Take injection molding – it depends on hollows packed with melted plastic. On the flip side, die casting uses locked steel pockets that clamp tight while liquid metal pours inside.Even within casting alone, sand-based forms behave unlike permanent metal dies.

Meanwhile, stamping operations depend entirely on precision dies rather than any cavity-style mold. Each sector picks its path based on needed volume, detail level, plus whether the material flows like water or moves like foil. Choices shift further due to heat levels involved, cycle times expected, or durability demands placed on the tool itself. Some applications call for expendable patterns formed once only, others need tools surviving millions of hits. Industry shifts bring new coatings, smarter maintenance routines, tighter tolerances. Firms specializing in long-run reliability or rapid setup often lead these changes behind the scenes. Knowing which route fits depends less on tradition, more on physics matched to output goals.

1. What Are Molds?

Definition of Molds

Molded shapes begin life as empty spaces, ready to receive something soft or runny. After filling, the substance rests until firm, copying every curve of its container. Out comes an object shaped exactly like the space that held it. Products made this way range widely – plastics, rubber bits, pottery forms, metal chunks, ornamental objects – all born from this repeatable transformation.

Frequently, molds play a role across many production paths – take injection molding, for instance. Sometimes metal gets forced into forms under pressure, known as die casting. Other times, loose grains hold the shape, like in sand mold. Plaster mold, giving structure through hardened coatings. Even Centrifugal casting rely on them, where rotation helps form pieces evenly.

How Molds Work

Poured hot, a substance like melted plastic or metal flows into a shaped cavity. That container locks it into the form meant for the final item. Once cooled down, or set by chemical change, the piece comes free. Out pops what was made, holding its new shape.

Take injection molding. Heat turns thermoplastics or thermosets liquid before they get shoved into molds under heavy force. After cooling down, out pops the piece – set for whatever comes next.

Main Types of Mold

Some molds stand out more than others, depending on what they shape. One kind fits plastics, another handles metals. Each version matches a goal in mind. Their design shifts based on the substance involved. Production needs decide their form. Size matters too, but so does cooling speed.

The way it opens affects output rate. Material flow guides structure choices

1. Sand Mold

Frequently found in processes involving poured metal. While sometimes applied elsewhere, its primary role stays within casting operations where molten material takes shape in molds.

Inside the mold, grains hold shape after surrounding the model. Grains stay fixed once shaped by the form within.

Into the mold flows molten metal, filling the space before hardening into form.

Few materials beat sand when shaping big metal parts. Often found holding molds for engine frames. Heavy-duty pieces come from this method. Molds form around patterns using damp grains. Sometimes reused, sometimes scrapped after one pour.

2. Plaster Mold

A smooth plaster mix takes the place of sand when shaping the mold space.

A glass-like result shows up more often compared to traditional sand methods. Smoothness comes through clearly when swapping out coarse molds.

Fine when working with softer metals that melt at lower temperatures.

3. Centrifugal Molds

A spinning mold takes liquid material during rotation, shaping it evenly as centrifugal force pushes outward. This method relies on motion rather than pressure to form consistent walls across complex shapes.

Flinging outward, material spreads across the inside wall. Spun fast, stuff presses against the curved edge. As rotation kicks in, particles slide sideways into place.

Fine shape holds steady in tubes, hoops – stuff built thick and even. Round things stay true when the makeup runs consistent throughout.

4. Injection Molding

Out there among machines that shape things, one stands tall when it comes to plastic stuff – injection molding. Pressure pushes hot goop into a custom-carved space inside metal walls, forming pieces bit by bit. Precision cuts define those hollows where liquid turns solid in seconds. Worldwide factories rely on this method more than many others you might name.

Injection Molding Process Explained

Material Preparation

Into machines go plastic beads, warmed after a drying spell. Heat wakes them up, readying their flow.

Injection

Poured under intense force, the liquid metal moves through a narrow opening into the shaped space.

Cooling

Once cooled, the substance hardens within the mold. Inside the form, it turns firm as temperature drops. As chill sets in, the stuff becomes fixed in shape. The mix grows stiff there when losing heat. With cooling, its state shifts to solid inside the cavity.

Ejection

Once the shape holds firm, out it comes – pushed by small rods that slide forward. A brief pause happens before movement begins again.

Key Advantages

- High production rate with automatic cycles

- Excellent part repeatability and precision

- Fewer workers needed after installation finishes

- Can produce highly complex geometry

Common Applications

- Consumer electronics housings

- Fancy bits on cars along with the parts that link pieces together

- Medical components

- Packaging

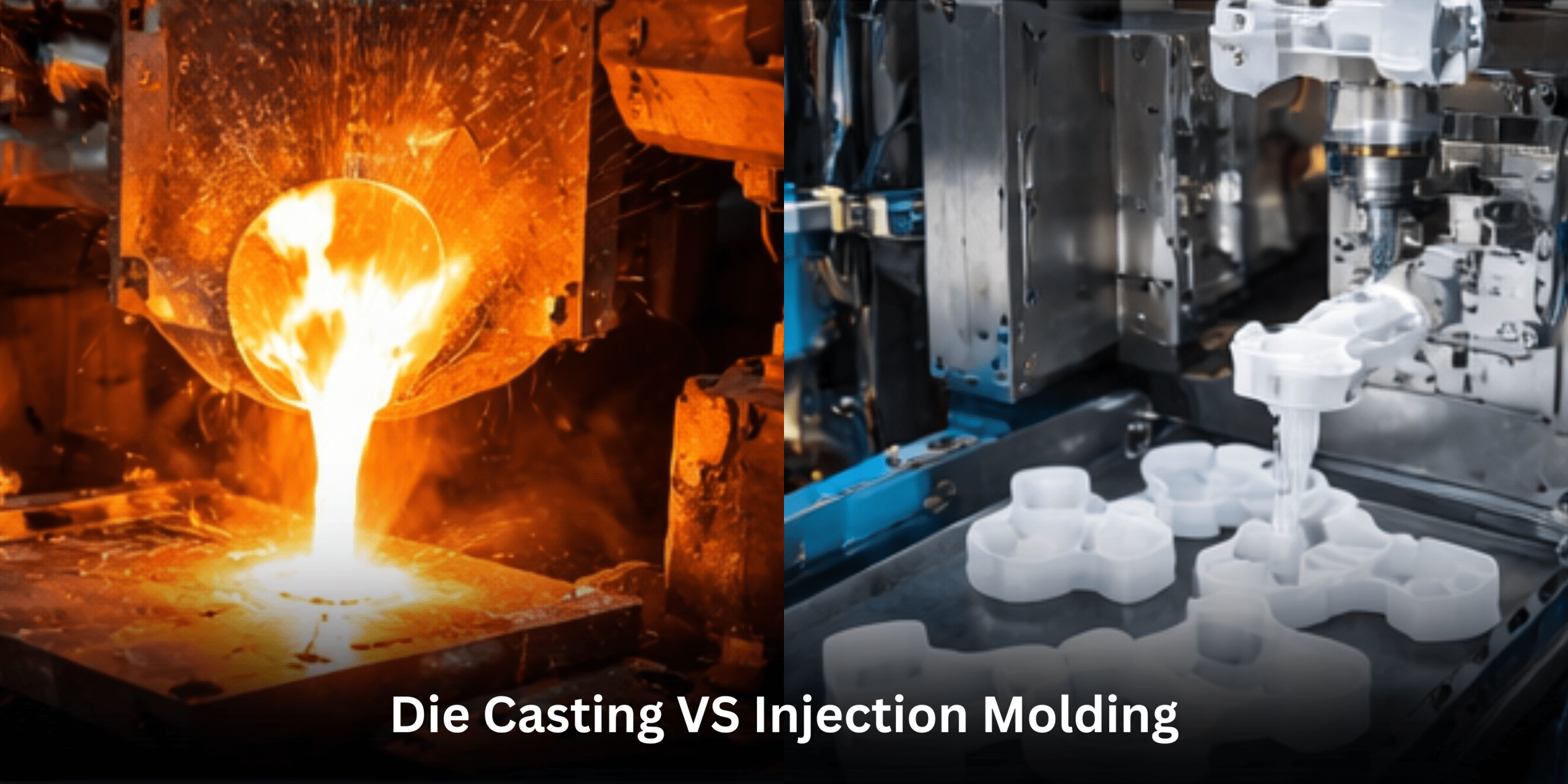

Even though molds play a role in injection molding, people often mix it up with die casting since each relies on cavity-based tooling. Still, plastic tends to be the main material in injection molding. On the flip side, metals take center stage in die casting, where dies shape the parts instead.

Why Molds Are Needed

Molds are used when:

- Fewer runs won’t cut it when making car plastics at scale. Production needs stay high just to keep up.

- Repeating intricate shapes without fail. Every time it must match, no exceptions. Precision holds everything together here.

- Fine surfaces come first when precision matters. Close margins follow without exception. Finely tuned details make the difference every time.

- Liquid stuff takes form only while wet. Once it hardens, changing shape gets tricky.

Common Ways Molds Are Used

- Plastic housings and items (phones, appliances) using injection molding

- Cast metal parts using sand mold or plaster mold methods

- Hollow parts like bottles via rotational molding

- Industrial components requiring precision surface finish

Out of nowhere, precision meets pace when makers turn to molds. Orbitol Intelligence Pvt. Ltd., among others, steps in with clear guidance – picking smart molding paths for plastic or metal shapes things differently. Tool strength grows while workflows tighten, almost silently improving output.

2. What Are Dies?

Definition of Dies

Starting off, dies are tough tools made for shaping stuff like metal in factories. These tools press down hard on something flat, say a piece of metal, changing its look through force alone. Shaping happens fast when the die slams into place, forcing the material to bend or stretch. Melting never occurs because heat stays out of the process entirely. The result? A clean new form stamped exactly where needed.

Forged shapes begin life when metal gets pressed between heavy molds. Stamping follows a similar path, yet relies on quick hits to form parts. Instead of hitting, extrusion pushes material through a cutout to match its shape. Bending takes another route entirely – forcing curves with steady pressure. Each method leans on dies, though they act in very different ways.

How Dies Work

A heavy squeeze pushes the substance into form as the piece rests where upper and lower dies meet. Instead of gentle touches, tools such as presses apply strong hits – this forces the metal to twist, pull apart, snap along lines, or shift entirely out of shape.What emerges matches the form cut into the dies. Operation happens only under strong, steady load.

Starting with solids instead of liquids, dies shape material either cold or hot. Molds do it differently – those need fluid stuff poured in first.

Main Types of Dies

1. Open Die

- Flat surfaces press into metal, shaping it through basic tools. Pressure forms the material without complex designs nearby. Shapes emerge when force meets smooth contact points. The process relies on straightforward setups throughout. Minimal details define how the surfaces interact during compression.

- Stuff moves without trouble until it hits a block from the mold.

- Forging big or uneven forms happens here. Sometimes handles pieces that don’t fit standard molds. Shapes outside the usual pattern get made this way. Irregular sizes come through when needed. Large builds start like this.

2. Closed Die

- Often called closed-die forging instead. This method shapes metal using two dies that come together tightly.

- Wrapped around the piece completely, die cavities form a sealed space. The work sits entirely within their enclosed shape.

- Shape forms exactly once material settles into space. The mold holds firm while substance flows fully inside.

- Frequent within aerospace, also seen in car manufacturing forgings.

3. Casting Die

- Poured under intense force into a steel mold – that’s how die casting works with liquid metal such as aluminum or zinc. The material takes shape quickly once it fills the cavity of the hardened tool. Pressure holds it firm until solidification begins within the durable chamber.

- Not quite molds, though they look alike – die casting relies on metal forms while pressing harder than old-school methods.

4. Trimming Die

- After shaping metal through casting or forging, leftover bits get cleared away during this step. Removing extra pieces happens once the basic form is set. Flash tends to appear around edges – this process takes care of that. Excess material comes off when the part moves past first-stage production. Trimming follows forming, cleaning up rough areas left behind.

- Precision begins at the edge, holding shape through exact measures. A steady line defines it, followed by consistent sizing that just fits.

Why Dies Are Used

Dies are essential when:

- High precision metal forming is required

- Components need strong structural properties

- Sheet metal components are being produced (e.g., car bodies)

- Shaping metal pieces through molding fails when heat resistance gets too high. Strength demands often block this method entirely. Molding quits where metals demand more toughness. High temperatures shut down typical forming routes. Toughness needs push molding out of reach. Heat levels rise beyond what molds can handle.

With dies, jobs like cutting or stamping become faster because they keep each piece identical. Fewer hands involved once machines take over routine jobs, since they never tire. Identical results pop up each cycle – accuracy climbs without effort. Instead of handcrafting each item, tools shape materials with little variation. Over time, effort drops as output stays steady.

Common Applications of Dies

- Sheet metal stamping for automotive panels

- Extrusion dies for profiles like pipes and rods

- Die casting parts using casting die tooling

- Cutting and trimming operations

When it comes to mass-producing parts, picking the correct die tools matters a lot. Orbitol Intelligence Pvt. Ltd. steps in here, guiding makers through choices that fit their needs. Their support tweaks how presses run, making each motion more efficient. Because of these adjustments, cycles take less time without losing quality. Speed builds up naturally when every phase works smoother than before.

3. Key Differences Between Molds and Dies

Differences Explained

| Feature | Molds | Dies |

| Primary Goal | Shapes material in liquid or pliable form | Shapes solid material |

| Materials Processed | Polymers, rubber, molten metals (like in die casting) | Solid metals and hard plastics |

| Process Type | Injection molding, casting (e.g., sand mold, plaster mold, centrifugal) | Stamping, forging, cutting |

| State of Material | Liquid or soft | Solid |

| Tools Used | Molding cavities | Die sets |

| Surface Finish | Smooth and detailed | Precision edges and structural integrity |

| Typical Industries | Consumer goods, plastics, ceramics | Automotive, aerospace, metal fabrication |

| Complexity of Shape | Can be more intricate | Usually simpler or repetitive shapes |

Understanding Variations Clearly

- MOLDS: When a runny material takes shape, it often happens inside molds – these act as holders during the change. A mold gives form while the substance shifts from fluid to firm.

- DIES: Shaped by force, dies act as molds for cutting or forming solid metal. Though unseen, they’re essential in turning raw chunks into precise forms. Metal pressed between them takes on new shapes under pressure. Not always visible, these tools define edges through sheer strength. Each die pair works silently, crafting consistency out of hardness

Shaping materials often relies on molds – common in injection methods alongside age-old practices such as forming shapes with sand or plaster. Tools known as dies take center stage when pressing, hammering metals, or squeezing them into form through techniques like open or enclosed forging and die-based casting.

Choosing the Right Tool for Your Manufacturing Needs

What decides mold or die choice comes down to multiple aspects

Material Type

- When handling plastics or molten metal, molds come into play. These forms shape materials under pressure. Injection setups rely on them just as much as simpler methods do. Each mold holds a design until the substance inside hardens. Without such tools, consistent shapes would be difficult to achieve

- Bent on shaping metal pieces? Tools called dies come into play. When sheets meet force, these components mold them. Solid chunks get pressed too – same gear does both jobs

Production Volume

- When output needs stay high and items look exactly alike, either a mold can work just fine or a die might do the job equally well

- One part at a time? Soft tools might work better. Custom shapes often need bendable forms instead of heavy steel. When output stays small, simpler methods make sense. Fewer pieces mean basic systems can handle the job. Molds that adapt easily help when changes happen fast. Tiny batches rarely justify complex machinery

Product Geometry

Complex shapes with detailed features → Molds

Precision metal forms or structural parts → Dies

Cost Considerations

- A mold can set you back more at first – particularly if it’s big or built for multiple parts. Cost jumps up when complexity goes in. Larger designs take more material, that adds up fast. Multi-cavity versions need precise engineering, which pushes price higher. Starting out, expect a steeper number on the tag

- Creating dies often needs costly materials built to handle heavy use. Equipment must measure exactly, down to the smallest part. Spending more up front helps avoid constant repairs later. Tough alloys resist wear when shaping metal parts. Tools shaped precisely cut down on mistakes during production. Long-term savings come from fewer replacements over time

Industry Knowledge and Help

Working alongside specialists such as Orbitol Intelligence Pvt. Ltd. opens clearer paths to picking the right molds or dies. Their insight digs into long-term expenses, not just upfront prices. With their support, factories weave in automated steps that lift returns over time. Choices become sharper when experience guides the way.

Conclusion

A factory’s path often splits at the tooling crossroads: one route leans on molds and dies – each pulling results in opposite directions. When stuff flows like syrup, whether molten plastic or metal, holding it takes a mold’s hollow embrace. Dies work harder when solids resist, pressing sheet metal into shape or slicing through firm blocks with sharp intent. Speed, cost, finish – these aren’t decided by chance but by which tool grabs control early.

From plastic housings shaped through injection molding to metal parts formed by die casting, every method serves a distinct purpose. Sand molds come into play when casting complex metal forms slowly. Open die and closed die processes handle heavy-duty metal shaping with precision. Knowing how each one works makes all the difference. What matters most is matching the process to the part’s demand.

When it comes to sharp advice, smart software, because real results matter – Orbitol Intelligence Pvt. Ltd. is who experts turn to. Performance climbs when insights fit just right, while custom systems shape what factories aim to become. Tools evolve only if they match actual workflows, so precision stays high across every output. Vision becomes routine through steady upgrades, since experience guides each design choice made.