Micro machining has become an essential component in today’s manufacturing world, where reliability is critical and accuracy and precision are measured in microns. In the domains of aerospace, medicine, and defence, even small dimensional changes can result in major problems with function, safety, or compliance. Micro machining is therefore no longer just a specialised skill but is now necessary across the industry.

As products get smaller, lighter, and more complex, manufacturers must employ new methods. Successful manufacturing now depends on precise engineering and stringent accuracy requirements. In aerospace, medical, and defence work, maintaining tolerances at the micron level guarantees that every component functions as intended.

Understanding Micron-Level Tolerances in Precision Engineering

One millionth of a millimetre in size is called a micron. Working at this scale in precision engineering means handling dimensions that are invisible to the human eye. These tolerances are about long-term performance, repeatability, and functional reliability rather than aesthetic perfection.

Micron-level accuracy guarantees the following when producing precision parts:

- Appropriate component mating

- Decreased wear and friction

- Better distribution of workloads

- Greater product life

Tolerances have a direct impact on how parts respond to stress, temperature changes, and continuous operation in precision machining.

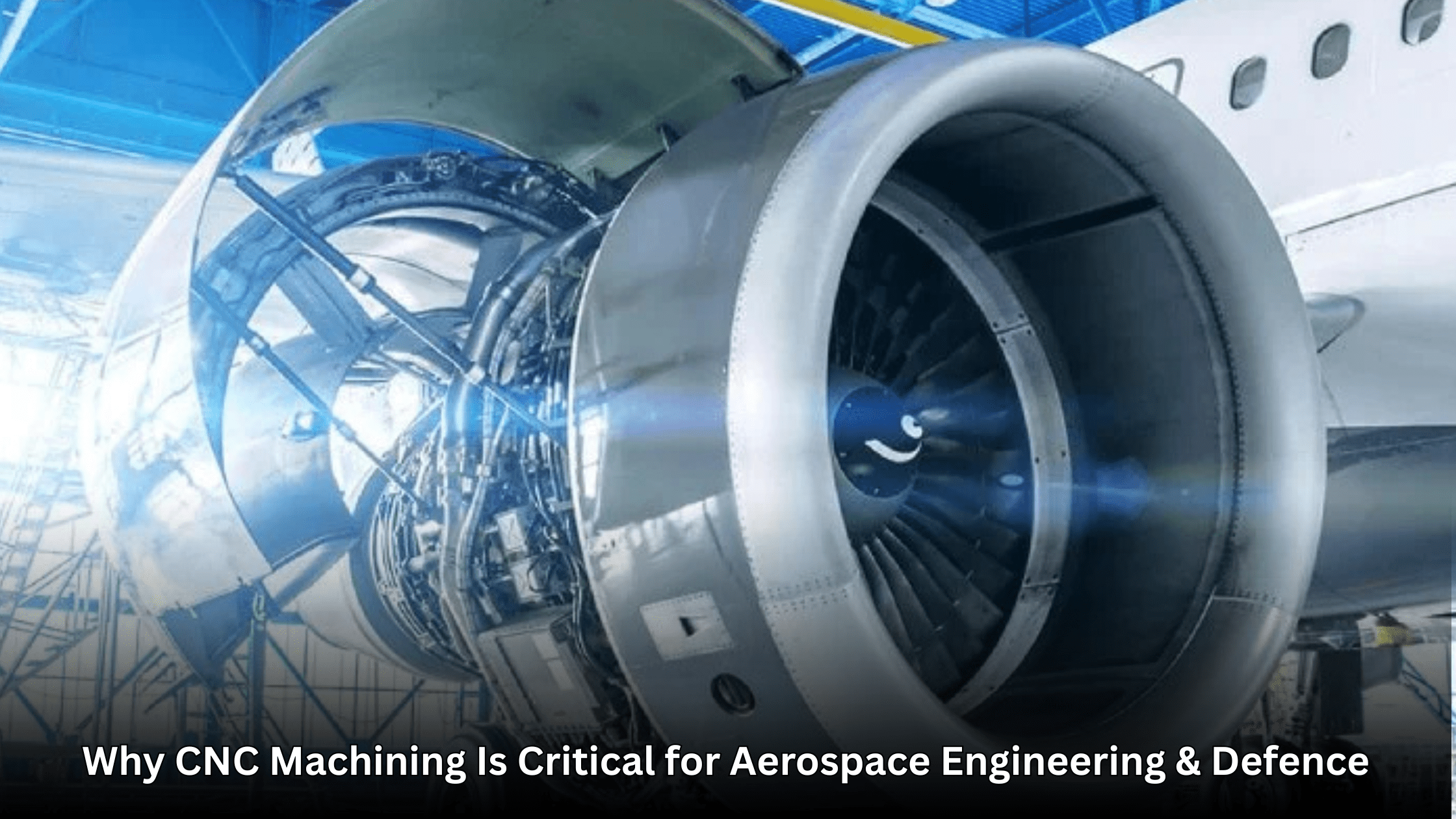

The Demand for Micro Precision in Aerospace Components

Extreme circumstances Need Total Precision

High speeds, severe pressure, vibration, and temperature swings are among the conditions in which aerospace components operate. Even a small dimensional error in aerospace machining can have an impact on structural integrity, airflow, and balance.

Parts like:

- Parts of the fuel system

- Actuator assemblies

- Brackets for structures

- Housings for turbines

To guarantee performance and safety, intricate machining and constant high precision are needed.

Micro Machining in the Production of Aerospace

Manufacturers can produce thin-walled structures, tight internal geometries, and complex features that are frequently found in aerospace components by using micro machining. Conventional machining techniques cannot consistently produce these features.

When combined with micro machining, advanced machining technologies allow:

- More effective surface treatments.

- Complete dimensional control.

- Decreased errors in assembly.

- Enhanced dependability of components.

The Role of Micro Machining in Precision Medical Devices

Tolerances have a direct effect on patient safety in medical manufacturing. Strict performance and regulatory requirements must be met by medical equipment and devices. An implant or surgical tool may experience discomfort, malfunction, or failure due to a small dimensional deviation.

In particular, micro precision is essential for:

- Implants for orthopaedics

- Surgical tools

- Diagnostic elements

- Devices that are minimally invasive

The Significance of Micro Machining in Medical Manufacturing

Micro machining makes it possible to:

- Biocompatibility through smooth surface finishes;

- Precise dimensional uniformity between batches;

- Enhanced dependability of functionality;

- Commitment to universal medical standards;

Micro machining guarantees that every component operates reliably in practical medical applications when paired with precision machining and accuracy and precision controls.

Defence Manufacturing: The Role of Microns in Mission Success

Defence components must function perfectly under erratic and often difficult circumstances. It is not optional to be precise.

In defence manufacturing, engineering precision ensures:

- Interchangeability of parts

- Smooth operation of the machine

- Long-term durability

- Decreased probability of failure

Micro machining supports defence applications by offering precise tolerances in parts used for guidance systems, weapon assemblies, and mechanical subsystems where quality is extremely important.

Swiss Machining: Transforming Micro Precision

Swiss machining is essential for creating complex, small parts that need to be highly precise. It works especially well on long, thin parts that are frequently used in medical and aerospace applications.

Advantages of Swiss Machining

| Feature | Benefit |

| Guide bushing support | Superior dimensional stability |

| Single-setup machining | Reduced tolerance stack-up |

| High repeatability | Consistent quality |

| Excellent surface finish | Improved performance |

Swiss machining is widely used for complicated cylindrical components where precision control is essential, precision shafts, and CNC turned parts.

Integration of Micro Machining and CNC Turned Parts

Turning and micro machining processes are increasingly combined in modern CNC machining parts. Micro machining improves concentricity, surface finishes, and tolerances for CNC-turned parts.

This integration facilitates:

- Decreased secondary operations.

- Quicker cycles of production.

- Enhanced accuracy and precision.

How Product Reliability Is Improved by Complex Machining

Manufacturers are able to produce numbers of characteristics of components in a single setup due to complex machining. This enhances dimensional consistency and lowers alignment errors.

Advantages consist of:

- Enhanced mechanical efficiency.

- Decreased problems with assembly.

- Increased dependability under load.

Complex machining becomes an effective tool for producing dependable, high-performing products when paired with precision engineering.

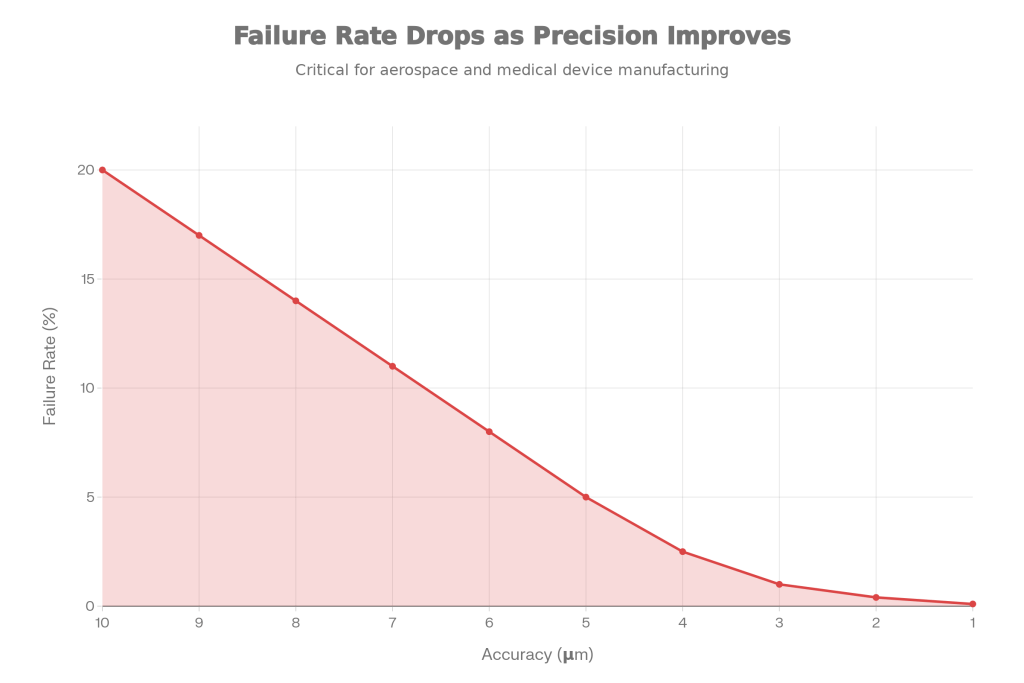

Graph Insight: Accuracy vs Failure Rate

Trend:

As dimensional accuracy improves, failure rates decrease sharply—especially in aerospace and medical applications. This visual strongly reinforces the value of micro machining for decision-makers.

Why Precision Control Is More Important Than Ever

Accuracy is maintained not only during machining but also during the entire production process thanks to precision control. This comprises:

- Monitoring of tool wear.

- Temperature adjustment.

- Inspection during the process.

Sustaining accuracy and precision throughout the entire process lowers scrap, increases yield, and boosts customer confidence.

How Orbitol Delivers Micro Machining Excellence

At this stage in the manufacturing journey, choosing the right partner matters. Orbitol combines micro machining, advanced machining, and deep precision engineering expertise to support aerospace, medical, and defence customers.

Orbitol’s capabilities focus on:

- High-precision micro machining

- CNC machining parts with tight tolerances

- Swiss machining for complex precision parts

- Consistent quality backed by engineering discipline

By aligning technology with process control, Orbitol helps customers achieve reliability, repeatability, and long-term performance across demanding applications

Table: Industry Requirements vs Micro Machining Benefits

| Industry | Key Requirement | Micro Machining Benefit |

| Aerospace | Structural reliability | Tight tolerance control |

| Medical | Patient safety | Ultra-smooth surfaces |

| Defence | Operational durability | Precision under stress |

| Industrial | Consistency | Reduced wear & failure |

Future of Micro Machining in Precision Manufacturing

As designs continue to evolve, micro machining will become even more critical. Smaller components, tighter tolerances, and higher performance expectations will push manufacturers toward:

- Smarter CNC systems

- Automation-driven precision control

- Advanced materials machining

Micro machining will remain central to the future of precision engineering across industries.

Conclusion: The Significance of Microns in the Modern Universe

Unwavering precision at every stage of manufacturing is essential to the success of defence, medical, and aerospace product production. Manufacturers can achieve micron-level tolerances through micro machining, which directly affects long-term dependability, operational safety, and product performance. Extremely accurate production results in components that fit better, function consistently, and endure extreme operating conditions without premature wear or failure.

Manufacturers can successfully meet the toughest worldwide quality and compliance standards by combining advanced machining technologies, Swiss machining capabilities, and disciplined precision machining processes. In highly regulated industries, micron-level accuracy is a strategic advantage that lowers risk, boosts overall product value, and improves reliability. It is not just a technological advancement.

The demand for smaller, lighter, and more complex components in the aerospace, medical, and defence industries will only increase the significance of micro machining. It will continue to be a major force behind innovation, paving the way for the next wave of high-performance manufacturing where accuracy, dependability, and quality are essential.